products - API 674 Reciprocating pumps

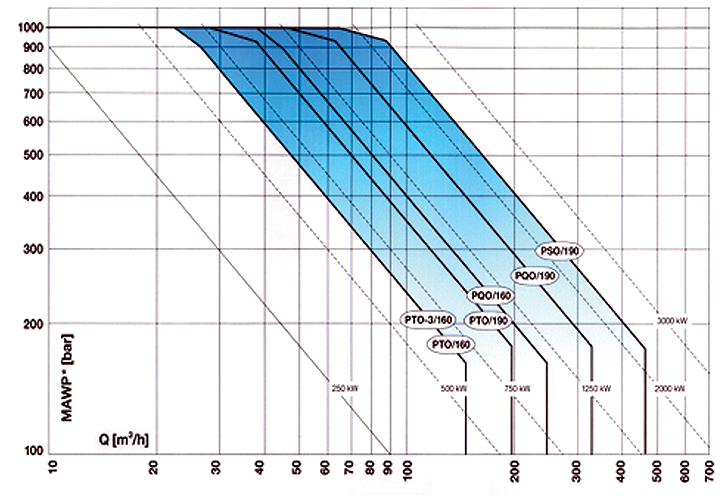

PTO/PQO/PSO Series up to 2500 kW

PTO/PQO/PSO Series up to 2500 kW

Description

The pumps of the PTO-PQO-PSO series comply with API 674 and ASME standards and are specifically designed and manufactured for process applications where continuous heavy duties are involved, demanding highest operating reliability and longest maintenance intervals.

The pumps of this series are made in horizontal execution, a solution providing several advantages if compared with the vertical one and which has been chosen by Peroni since the mid 60's, when the production of vertical pumps was basically discontinued.

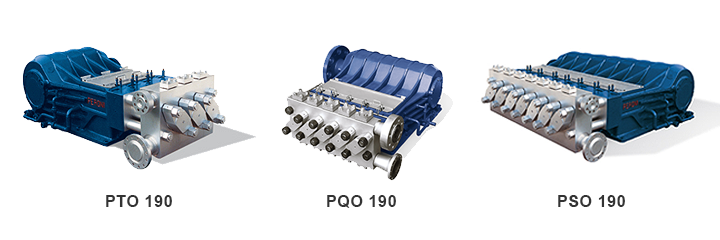

The series includes two pump sizes, 160 and 190. For each size triplex and quintuplex versions are available together with a septuplex model for the 190 size.

Quintuplex or septuplex pumps, compared with a triplex pump of equivalent performances, have reduced static and dynamic loads and lower pressure pulsations which simplifies piping design. Thus result higher reliability, less maintenance and smoother operation of the pump.

The PTO/PQO/PSO series covers the highest range of performances required by the market of reciprocating pumps and its flexible design allows the installation of both plunger and piston type liquid ends.

Crankmechanism

The main features of the crankmechanism of this series are:

- Continuous shaft support is obtained with individual sleeve bearings for each plunger, with reduced stresses making them intrinsically safe against shaft failure.

- Connection of the plunger to the crankmechanism through a spherical joint with subsequent limited loads on the sealing area.

Liquid end

In order to meet the different requirements of the process applications connected with various operating conditions and fluid characteristics, the hydraulic end is defined by combining different configurations of the manifold, valve assembly and sealing systems and by selecting the most suitable materials for each specific application.

The standard hydraulic end arrangement is suitable for a wide range of operating conditions, hazardous fluids and/or containing suspended solids.

Other hydraulic solutions are available for high viscosity fluids and pumping conditions at high or low temperature.

Specific liquid end designs are also available for handling slurries with a significant content of solid particles (in terms of size and weight percentage).

Valves and sealings

Various types of valves are available to meet the NPSHa conditions and the characteristics of the different fluids handled in terms of viscosity and solids content.

Furthermore, Peroni studied many sealing systems and the design of each of them is suitable to solve the problems connected with the physical characteristics of the fluid handled and the risks connected with its contact with the atmosphere.

Performances