products

process diaphragm pumps

Process Diaphragm Pumps

Description

The concept of a Process Diaphragm Triplex Pump is a fixed stroke reciprocating plunger pump where the process fluid is handled by means of a diaphragm actuated through an intermediate fluid.

The reciprocating movement of the plunger displaces the oil contained in a pump chamber which in turn moves a diaphragm housed in the front end of the pump. The process fluid is sucked and discharged by the alternate bending of the diaphragm which avoids that the process fluid enters in contact with other parts of the pump and with the atmosphere.

Process Diaphragm Pumps are a version of the TITANO and the PTO/PQO/PSO Reciprocating Plunger Pumps Series and use standard power ends and liquid ends with hydraulically actuated diaphragms.

This solution is used for handling any hazardous fluid, when stringent environmental regulations have to be met and when the plunger leakage free solution is not accepted within the project.

Crankmechanism

The power end is the same widely used for API 674 Titano and PTO/PQO/PSO Reciprocating Plunger Pumps.

Liquid end

The series is designed adopting hydraulically actuated double diaphragms with intermediate safety chamber.

The main solutions adopted for the liquid end design are the following:

Patented DELTA geometry of the liquid end design that allows:

- minimized overall pump dimensions and weight

- high stiffness of the liquid end with very limited deformation under severe loads

- reduced clearance volumes with consequent high value of the volumetric efficiency

- reduced volume of oil requested to actuate the diaphragms since the plunger sealing does not require to be oil flooded

- standard execution with high strength modified PTFE double diaphragm, sandwich type

- monitoring of diaphragm failure

- proprietary diaphragm shape and assembling system design that avoid stress concentrations

- incorporated relief valve, easily accessible for routine maintenance, to prevent any damage to the pump in case of accidental overpressure

- internal recirculation valve, to restore the driving fluid if the relief valve opens, with active push rod for diaphragm displacement control under high pressure suction conditions

Advantages of the series

All the Diaphragm Process Pumps are designed and manufactured considering the applicable API 674 and ASME standards so that all the components of the pumps are designed with high safety factors that lead to a very rigid and safe construction and to limited life cycle costs.

Peroni Process Diaphragm Pumps are specifically designed for off-shore applications with footprints reduced up to 25% compared to other manufacturers’ pumps.

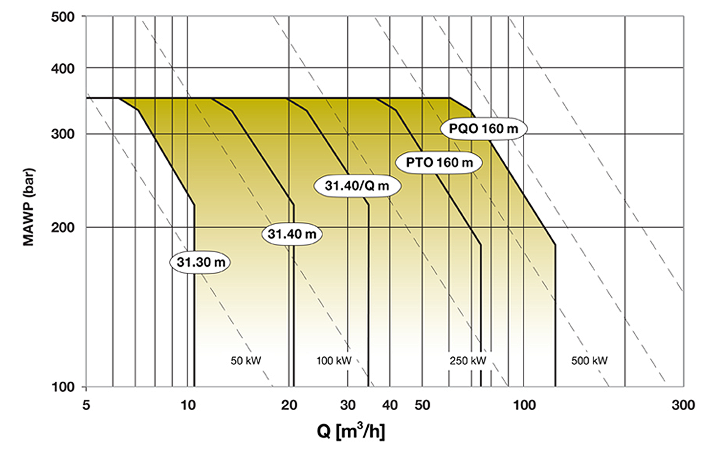

Performances