company

History

History

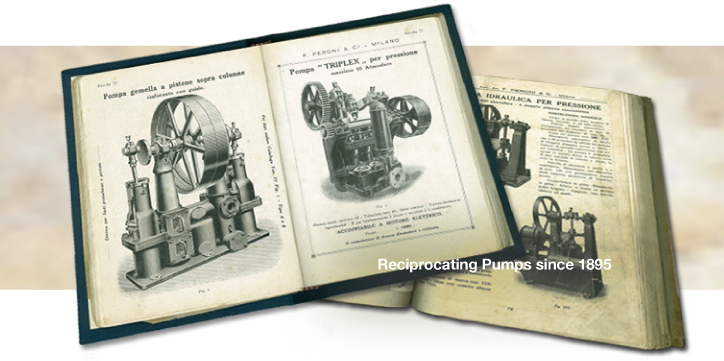

| History | Technological Milestones | |

| The Company is established in Milan | 1895 | |

| 1902 | Peroni designs its first steam driven pump | |

| Peroni catalogue shows various types of reciprocating pumps | 1908 | |

| The manufacturing program includes different lines of products and among them reciprocating pumps for industrial and civil applications | 1930 1940 | |

| Peroni moves to new premises where the production activities remain up to 1994 | 1945 | |

| The Company adopts a policy of technological specialization concentrating its activities on the designing and manufacturing of reciprocating pumps | 1950 | |

| 1952 | Peroni designs and manufactures the pumps requested by the pilot plant for the first urea installation in the world | |

| Peroni starts supplying its pumps for the new and growing Italian petrochemical and refining industry | 1955 1970 | |

| 1964 | Design of the first large size horizontal triplex pump | |

| 1968 | Design of the first pump for detergent slurry | |

| First supply of pumps for offshore installation | 1976 | |

| 1979 | Design of a pump for the first Coal Liquefaction pilot plant in UK | |

| A Quality Assurance System is introduced in the company organization | 1980 | Design of the first hydraulically driven grout injector for the new controlled micropile technology for ground consolidation in civil engineering |

| A second manufacturing plant is built in Gaeta in Southern Italy | 1983 | Design of the first pump for the new jet grouting technology used in civil engineering |

| 1984 | Design of a process-reciprocating pump for a Coal Slurry Pipeline | |

| 1994 | Design of the pumps for the new Residues Upgrade H-Oil process | |

| All the manufacturing processes are concentrated in the Gaeta factory for the optimization of the production activities | 1994 | |

| The Quality Assurance System is certified according to ISO 9001 standard | 1995 | |

| The R & D department is formally established and provided with specific software and hardware tools and a dedicated testing room | 1996 | |

| 1997 | Design of a specific Hydraulic End for one of the first Residues Gasification IGCC plant | |

| 1997 | Design of the pumps for the second LC - Finer Residues Upgrading installation in the world | |

| 2004 | Design and construction of a MEG Injection Unit for the pilot installation in Ormen Lange, Norway, of the MEG regeneration/reclamation system (Aker technology) | |

| The Environmental Management System is certified according to ISO 14001 : 2004 standard | 2004 | |

| 2005 | Patented automatic sealing packings adjustment system | |

| 2005 | New pumps for the first Coal Liquefaction industrial plant in the world | |

| Peroni Pompe moves to new premises including a state-of-the-art research center, located in the Milan area | 2008 | |

| Peroni’s factory in Gaeta is enlarged to increase production capacity: covered area + 50%, many new large machine tools, sandblasting and painting shops designed to satisfy the requirements of the offshore market | 2010 | |

| The Occupational Health and Safety Management System is certified according to OHSAS 18001:2007 | 2013 | Design of the pumps needed by the new BP Veba Combi-Cracker (VCC) technology for converting petroleum residues |

| Peroni’s Gaeta factory is enlarged further to become suitable for the growing number of jobs and the augmented sizes of the pumping units requested | 2015 | |

| A new 2,5 MW frequency inverter is installed at Peroni's Gaeta plant. The factory is now capable of testing the largest plunger pumps available worldwide | 2020 |